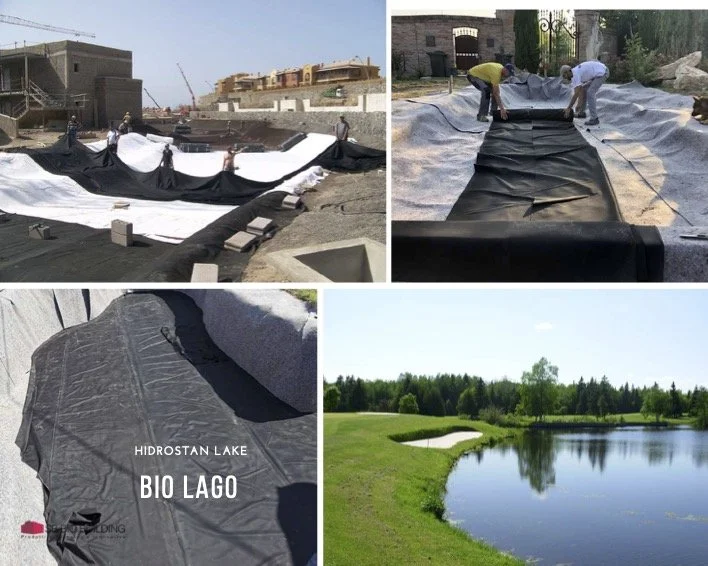

Home > HIDROSTAN® > References Waterproofing of Bio Lakes, Bio Pools, and Tanks

HIDROSTAN® References Waterproofing Bio Lakes, Bio Pools, and Tanks

Back to the beginning | go to Blog Articles

References and Documents

References

Papers

HIDROSTAN® Technical Data Sheets >

HIDROSTAN® Materials Kit

HIDROSTAN® Installation Manual

Brochure

Back to Blog Articles | Contact

Basic information

Procedures for laying EPDM membrane for the construction of a reservoir

Hidrostan® EPDM membranes stand out for their exceptional resistance to chemicals, perforation, andaging, guaranteeing decades of durability even under harsh operating conditions. Thanks to their high elasticity and flexibility, the membranes adapt perfectly to the geometry of the tanks, ensuring a continuous, seamless coating.

The design of a containment system is a crucial and delicate phase in the construction of tanks intended to hold large quantities of water. The correct design of these structures is essential to ensure operational safety, structural stability, and environmental protection.Among the first design considerations to be addressed, particular importance is given to the need to adequately compact the foundation soil and the slope and to lay any pipes for runoff water or gas in the ground first. This operation is essential to reduce differential settlement, improve soil bearing capacity, and prevent localized instability or uncontrolled water infiltration into the subsoil.

Hidrostan® EPDM membranes are certified according to EN 13361, a standard specific to the waterproofing of dams, reservoirs, and containment tanks, thus ensuring compliance with the highest Swiss and European standards in terms of safety, durability, and mechanical resistance. One of the distinctive features of Hidrostan® membranes is their extreme simplicity and speed of installation, which significantly reduces construction time and related installation costs. From a technical point of view, the membranes are distinguished by their exceptional flexibility, able to easily adapt to uneven surfaces or movements of the substrate, maintaining stable performance over a widetemperature range: from -40°C to +150°C. Furthermore, Hidrostan® membranes offer elongation of more than 300%, giving the material extraordinary mechanical resilience and resistance to deformation and dynamic stresses, which can be decisive for the durability of the waterproofing system.

Once the base has been prepared, a non-woven geotextile ( TNT) is laid, which protects the membrane, preventing direct contact with any roughness in the ground and promoting its durability over time. The TNT is securely fixed to the ground using anchoring forks, distributed evenly across the entire surface. Once the TNT has been laid, the Hidrostan® EPDM waterproofing membrane is laid , having been previously cut to size according to the configuration of the basin. The membrane must be laid with particular care so that it adapts precisely to the natural and irregular shapes of the lake, without creases or excessive tension, thus ensuring uniform and continuous coverage over the entire surface.

WHAT IS A RESERVOIR USED FOR? 1 ,600,000 results

With a view to mitigating hydrogeological instability, Hidrostan® EPDM membranes represent a highly efficient solution for the construction of various types of water containment systems.

Thanks to their excellent elasticity, resistance to UV rays, chemicals, and temperature changes, these membranes are used in the construction of reservoirs for agricultural irrigation systems, water storage basins in mountainous areas, and integrated infrastructure for hydraulic invariance and fire prevention. In these contexts, EPDM lining guarantees long-term impermeability, reducing infiltration losses and ensuring the structural stability of the works.

In an area increasingly subject to drought and reduced water availability —a condition that tends to recur cyclically due to climate change—there is now a widespread awareness that the construction of artificial reservoirs using Hidrostan® EPDM geomembranes represents the solution with the lowest environmental impact and the most economically sustainable. This technology allows for the optimal use of available water resources, ensuring their conservation and reducing maintenance costs over time.

The same technological solutions are also widely used in recreational and landscaping applications, in the construction of natural lakes and swimming pools, where EPDM membranes ensure the watertightness of the basin without altering the water quality and maintaining compatibility with sensitive aquatic ecosystems. In these cases, EPDM offers excellent workability and adaptability to complex surfaces, allowing the creation of irregularly shaped basins with high aesthetic value, harmoniously integrated into the surrounding environment.

Thanks to their decades-long durability, ease of installation, andlack of extraordinary maintenance, Hidrostan® EPDM membranes are confirmed as a technical benchmark choice for both agricultural and industrial applications, as well as for environmental and recreational projects, contributing in a concrete way to the sustainable management of water resources and the hydraulic safety of the territory.

Availability of water reserves

The availability of water resources is now one of the main critical issues at a global level, aggravated by reduced rainfall in some areas and increased demand linked to agriculture, industry, and civil use. In this context, the ability to accumulate, conserve, and manage water efficiently becomes a strategic objective for the water security of a territory. Thanks to their physical and chemical properties, EPDM (ethylene propylene diene monomer) waterproof membranes play a decisive role in maintaining water reserves, acting as a total barrier to dispersion.

Without waterproofing, any artificial reservoir or catchment is subject to significant leakage through the bottom and walls, especially in permeable or cracked soils. Eliminating this phenomenon and ensuring that the stored volume remains available for an extended period becomes a particularly important priority for catchment basins in arid areas, where every cubic meter of water preserved has strategic value. Waterproofing with EPDM allows peaks in water availability (e.g., during intense rainfall events) to be accumulated and stored without significant losses until needed, transforming the water into a manageable and programmable reserve. This aspect is crucial for preserving water purity, especially when it is intended for irrigating sensitive crops or for drinking purposes.

With a useful life of over 30 years,Hidrostan EPDM membranes are resistant to temperature ranges between -40 °C and +150 °C, reducing the need for extraordinary maintenance, cutting management costs and resource consumption for replacements or repairs. Life cycle analysis (LCA) also shows a reduced environmental impact compared to alternative solutions, thanks to less frequent replacement and low energy consumption during installation.

EPDM-waterproofed reservoirs as strategic infrastructure for fire risk prevention and management

In urban-rural interface areas, where homes and settlements are in direct contact with wooded areas or natural vegetation, the risk of vegetation fires is particularly high. Understanding how fire spreads is the first step in planning effective prevention and protection measures.

The first assessment when buying a house in wooded areas is to check its safety from fires, which often spread, direct exposure to flames, which can reach and affect nearby structures and vegetation, thermal radiation, which transfers heat even at a distance, triggering the combustion of flammable materials, and the transport of incandescent sparks (spotting), generated by the column of hot smoke and carried by the wind for hundreds of meters or, in extreme conditions, even for kilometers, triggering secondary fires.

In this context, the availability of an emergency water supply, such as a reservoir in the immediate vicinity of a home or production area, can make the difference between rapid and effective intervention and loss of control over the fire.

Fire safety guidelines indicate that a minimum water supply of 1.5 m³ for at least two hours of continuous delivery is required for firefighting operations to protect a dwelling. A waterproofed reservoir can be sized to provide much larger volumes, ensuring coverage not only for a single building but for an entire residential area. With adequate dimensions (water surface free of obstacles, absence of tall surrounding vegetation), an EPDM-coated reservoir can serve as a refueling point for helicopters.

Thanks to their decades-long durability, ease of cold welding, and adaptability to customized projects, Hidrostan® EPDM membranes are the go-to choice for sustainable water resource management, hydrogeological instability prevention, and landscape enhancement.

Back to top

Contact Form

Contact us now or leave your details below for a free professional consultation